Servo Injection Moulding Machine

Servo Energy Savings Series

| Main Hydraulic Index | Trishul Servo Index |

|---|---|

| Response Time of Pressure Rise 50ms | Response Time of Pressure Rise 50ms |

| Response Time of Flow Rise 40ms | Response Time of Flow Rise 40ms |

| Range of Pressure Fluctuations +0.9 Bar | Range of Pressure Fluctuations +0.9 Bar |

| KW.h/Kg : | Repeatability Precision |

| 1st Class <= 0.4 | Special Class <= 0.5 |

| 2nd Class > 0.4-0.55 | 1st Class > 0.5-1 |

| 3rd Class >= 0.55-0.7 | 2nd Class >= 1-2 |

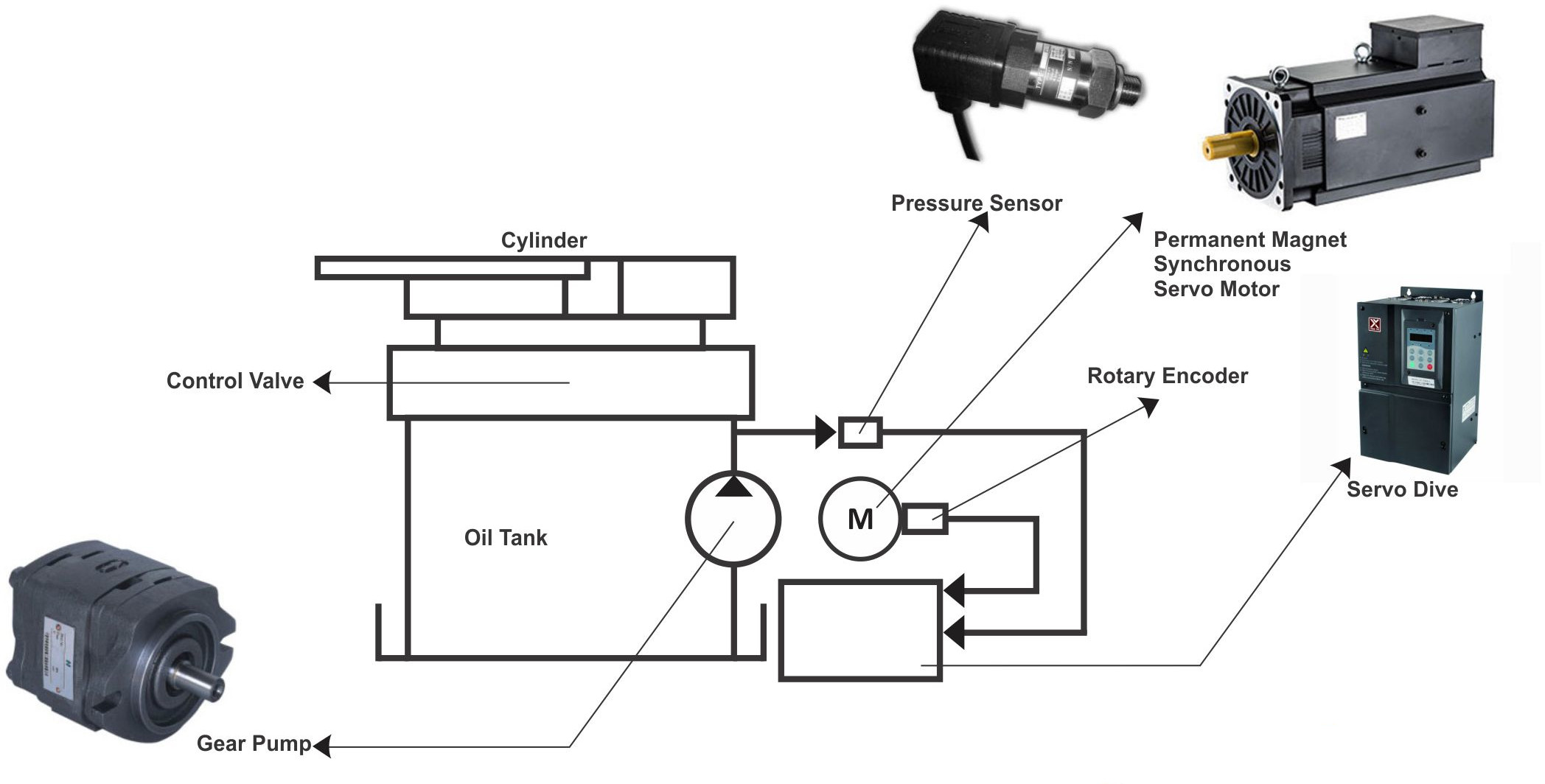

Servo Energy Saving Schematic Diagram

The Servo Energy Saving Plastic Moulding Machinery Configure Rotary Encoder And Pressure Sensor. So It Will Feedback The Flow & Pressure In Time. It Adjusts The Flow & Pressure by Changing The Servo Synchronous Motor's Rotate Speed And The Torsion to make Sure Higher Repeatability Precision, Maximum Energy Saving And The Production Efficiency.

Case:

| Test Product : | Disk |  |

| Plastic Material : | PS | |

| Product Weight : | 100g | |

| Product Wall Thickness : | 2.6mm | |

| Number of Mold Cavity : | 1 | |

| Test Condition : | Power Test Device Record 3 Series IMM's Value During Full Auto Producing When The Oil Temperature Stable at 45° C | |

| Comparison of IMM | 160T IMM | 160T IMM | 160T IMM | |

|---|---|---|---|---|

| Moulding Cycle Time | s | 20 | 20 | 20 |

| Test Time | h | 3 | 3 | 3 |

| Cycle Count | mold | 540 | 540 | 540 |

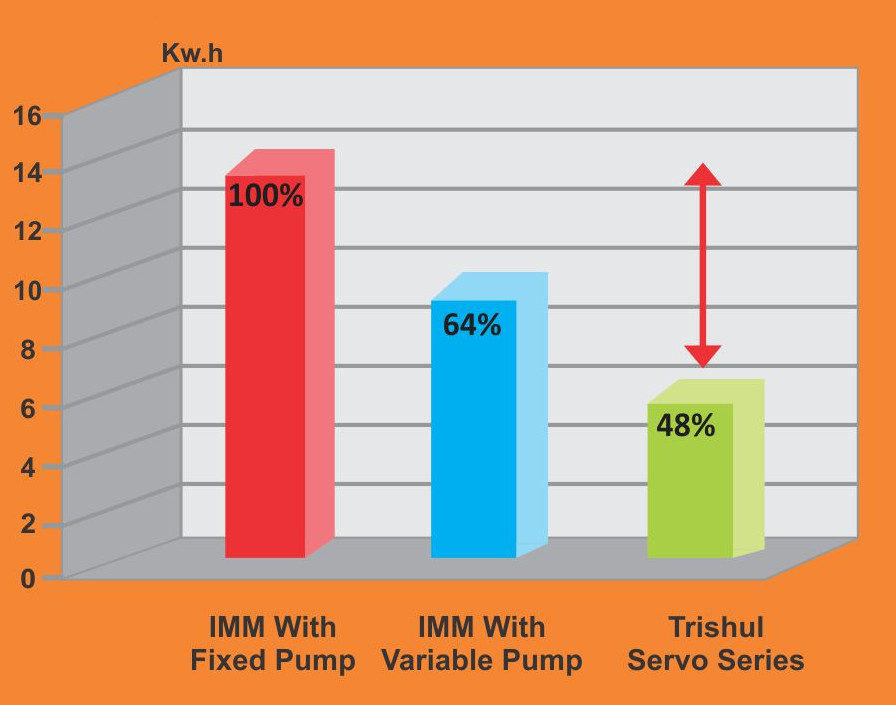

| Power Consumption/Hour | KW/h | 12.6 | 8.1 | 6.6 |

| Power Consumption/Year | KW/h | 83160 | 53460 | 43560 |

| Power Consumption/Kg | KW.h/kg | 0.7 | 0.45 | 0.36 |

| Effect of Servo Energy Saving | % | IMM With Fixed Pump | 51.6 | |

| IMM With Variable Pump | 24.7 | |||

The required energy consumption to produce the processing ruler by an energy saving machines are 51.6% less when compared to a traditional hydraulic imm and 24.7% less than imm with an optimized variable pump the energy saving machine also requires 80% less energy to produce a thick wall product which needs a longer holding & cooling time or 50% less than using an IMM fitted with optimized variable pump.

Special Features:

- Large Clamp Stroke, Efficient and Reliable Movement. Wear Resistance & High Quality Casng Platen Adopts Finite Element Analysis Design That Brings Even Stress Distribuon to Increase Mold Locking Precision. Self Lubricang Bushes Used In Guide Rods and Tie‐Bars For Smooth Running and Eliminang The Need of External Lubricaon of Machine Surfaces and Plasc Goods. Automac Mold Height Adjustment by Hydraulic Motor Through a Planetary Gears System Ensures Fast and Constant Sengs. Mul Eject Funcon With Adjustable Pressure, Speed, Posion And Delay Time. Low Pressure Mold Protect. Linear Potenometer For Mold Clamp Posion Control. Three Stages of Mold‐ OPEN/CLOSE, Pressure and Speed Control. Whole Covered Guide of Clamping unit Ensures The Operator’s Safety.

Optional Features:

- INJECTION MOLDING MACHINE Energy Efficient High Precision & Stable Moulding Quick Response & Low Noise

Automobiles

Automobiles

caps

caps

HOUSEHOLD

HOUSEHOLD

_1555850975.png) INSERT PARTS

INSERT PARTS

UPVC -PVC FITTING

UPVC -PVC FITTING

PET PREFORMS

PET PREFORMS

ALL FITTING

ALL FITTING

spoon plastic

spoon plastic